CHOOSE YOUR SOLUTION

COMEPLETE PRODUCTION LINE

COMEPLETE PRODUCTION LINE

OF BOTTLE WATER PRODUCTION LINE

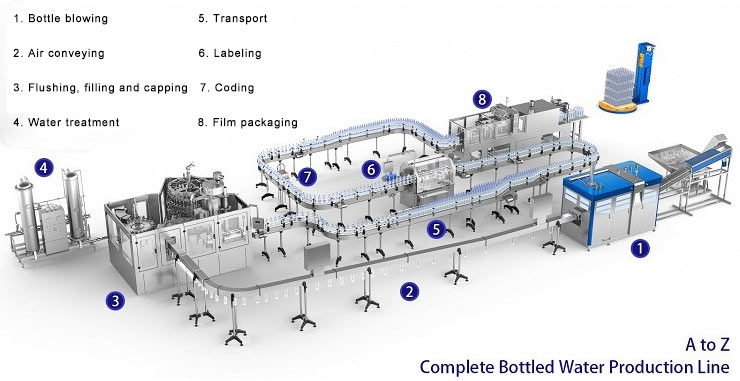

This production line can produce bottled mineral water, pure water. The capacity can be from 1000 bottles/h to 36000 BPH, bottles can be from 100ml to 2L.

We can provide complete line plants from A to Z, also provide turnkey solutions, layout design, bottle design, label design, and provide solutions according to your source water and target product. We can provide different customizations according to your request.

OF BOTTLE WATER FILLING PRODUCTION LINE

| Full Automatic Water Bottle 4000-24000bph Production Line | Bottle Water | |||

| Material | Shape | Filling volume | Capacity (bottles/hr) | Neck type |

| PET Bottle | Square or Round Bottle | 250-2000ml | 5000-6500 (≤500ml) | 26mm /28mm /30mm /38mm (one size) |

| Filling material | ||||

|

Mineral water, pure water, RO water, drinking water,

flavored water, still beverages More production volumes and models can be customized. |

||||

| Application | Water, juices, beverages ….. | |||

This production line can produce bottled mineral water, pure water. It is suitable for bottles of different sizes such as 250ml, 500ml, 1L, 2L, etc. The mineral water bottle filling machine is ingerated of washing, filling, capping, drying, labbeling, packaging machine. It adopts new technology and new structure, leading the development of the liquid filling and packaging industry.

Function: washing the bottle inside and outside to remove dust.

– All 304/316 Stainless steel rinse heads, water spray style inject design, save more water consumption, and are cleaner.

– 304/316 Stainless steel Gripper with plastic pad, ensures minimal bottle crash during washing.

Fucntion : filling water into bottle.

– 304/316 Stainless steel high precision filling nozzle.

– Filling volume adjustable in fine rank, same liquid level after filling.

– All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

– 304/316 stainless steel filling pump.

Function : put caps on bottle.

– Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping.

– All 304/316 stainless steel construction.

– No bottle no capping

– Automatic stop when lack of bottle

Function : Air conveyor for bottle transfer.

– Fixed to the floor with top-mounted fans, ensuring stable and efficient airflow.

– Equipped with air filters at each fan inlet to prevent dust from entering bottles.

– Bottles are secured by the neck and transported via air pressure to the filling machine.

Function: Conveying the finished product

– Quick transport for easy follow-up

– Modular design for seamless integration with filling/capping machines.

OF Bottle Water PRODUCTION LINE

Raw water pump

Quartz sand filter

Activated carbon filter

Softener

Safety filter

High pressure pump

RO system

Ultraviolet sterilizer or ozone generator

Provides pressure to quartz sand filter/activated carbon filter

Removes turbidity, suspended matter, organic matter, colloids, etc

Removes color, free chloride, organic matter, harmful substances, etc

Used to replace calcium and magnesium “ions” in water

Prevents large particle impurities from entering the RO membrane, with an accuracy of 5um

Provides high pressure to the RO membrane

The main part of the equipment. The desalination rate of the Ro membrane can reach 99% and removes more than 99% of ions

Kills bacteria

Bottle Warmer

The bottle warming machine is a tunnel-type spray equipment that heats the bottle body through heat exchange by circulating spraying hot water. It has three permanent temperature zones (more temperature zones can also be designed). After segmented heating, the temperature in the center of the beverage reaches room temperature. The inlet and outlet of the bottle warming machine adopt dynamic transition to reduce bottle extrusion and manual intervention.

Laser Date Printer

The CO2 laser printer marking machines are powerful and versatile, they deliver flexible, high speed, high quality coding across a wide variety of materials with the ability to produce multiple lines of text. Our laser marking machines are designed to fit in limited spaces and integrate into a variety of production lines.

Bottle Packing Machine

1. Suitable for opening and sealing cardboard boxes of various sizes. If you need to change the size of the cardboard box, you can manually adjust it, and the operation is simple and convenient.

2. The fully automatic grabbing boxing machine is reliable in operation, and the grabbing head is used to charge and exhaust to achieve the grabbing and releasing action of the bottles. Then, through mechanical action, the bottles are accurately placed into the cardboard box from the entire platform.

3. Manually adjust the width and height according to the specifications of the cardboard box; Automatic folding box top cover, automatic tape application up and down, economical, stable, and fast; Equipped with blade protection device.