CHOOSE YOUR SOLUTION

COMEPLETE PRODUCTION LINE

COMEPLETE PRODUCTION LINE

OF OIL PRODUCTION LINE

This production line is specially designed for oil filling, with a capacity range of 2,000 to 18,000 bottles per hour. It is suitable for both edible and industrial oils, such as peanut oil, palm oil, blended oil, and lubricants. Oil products require high precision and hygiene during filling, and their volatile nature can lead to adhesion and dripping on equipment surfaces.

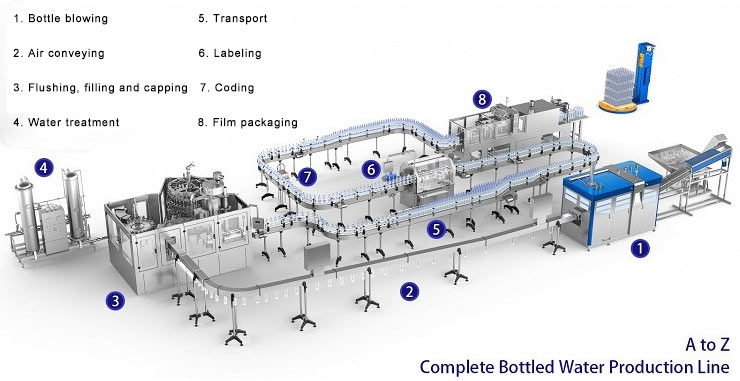

We can provide complete line plants from A to Z, also provide turnkey solutions, layout design, bottle design, label design, and provide solutions according to your source water and target product. We can provide different customizations according to your request.

OF OIL PRODUCTION LINE

| Full Automatic Water Bottle 2000-18000bph Production Line | Bottled oil | |||

| Material | Bottle Specifications | Cap Specifications | Capacity (bottles/hr) | Filling volume |

| PET Bottle | Φ270×490×Φ56 | Φ58×40 | 2000-18000 | 200ML-5L |

| Filling material | ||||

|

Mineral water, pure water, RO water, drinking water,

flavored water, still beverages More production volumes and models can be customized. |

||||

| Application | Water, juices, oil, beverages ….. | |||

This production line can produce bottled oil. It is suitable for bottles of different sizes such as 200ML-5L, etc. The oil bottle filling machine is ingerated of washing, filling, capping, drying, labbeling, packaging machine. It adopts new technology and new structure, leading the development of the liquid filling and packaging industry.

1

Function: washing the bottle inside and outside to remove dust.

– All 304/316 Stainless steel rinse heads, water spray style inject design, save more water consumption, and are cleaner.

– 304/316 Stainless steel Gripper with plastic pad, ensures minimal bottle crash during washing.

2

Fucntion : filling water into bottle.

– 304/316 Stainless steel high precision filling nozzle.

– Filling volume adjustable in fine rank, same liquid level after filling.

– All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

– 304/316 stainless steel filling pump.

3

Function : put caps on bottle.

– Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping.

– All 304/316 stainless steel construction.

– No bottle no capping

– Automatic stop when lack of bottle

4

Function : Air conveyor for bottle transfer.

– Fixed to the floor with top-mounted fans, ensuring stable and efficient airflow.

– Equipped with air filters at each fan inlet to prevent dust from entering bottles.

– Bottles are secured by the neck and transported via air pressure to the filling machine.

5

Function: Conveying the finished product

– Quick transport for easy follow-up

– Modular design for seamless integration with filling/capping machines.

OF Bottled oil PRODUCTION LINE

Bottle Blowing

The blow molding machine is specially designed for producing oil bottles ranging from 200ml to 5 liters. It is widely used to manufacture PET plastic containers in various shapes, with neck finishes typically from 28mm to 48mm, making it ideal for packaging edible oil, lubricants, and other liquid p

Laser Date Printer

The CO2 laser printer marking machines are powerful and versatile, they deliver flexible, high speed, high quality coding across a wide variety of materials with the ability to produce multiple lines of text. Our laser marking machines are designed to fit in limited spaces and integrate into a variety of production lines.

Bottle Packing Machine

1. Suitable for opening and sealing cardboard boxes of various sizes. If you need to change the size of the cardboard box, you can manually adjust it, and the operation is simple and convenient.

2. The fully automatic grabbing boxing machine is reliable in operation, and the grabbing head is used to charge and exhaust to achieve the grabbing and releasing action of the bottles. Then, through mechanical action, the bottles are accurately placed into the cardboard box from the entire platform.

3. Manually adjust the width and height according to the specifications of the cardboard box; Automatic folding box top cover, automatic tape application up and down, economical, stable, and fast; Equipped with blade protection device.