The gallon bottled water filling machine integrates rinsing, filling and capping, and is suitable for filling 3 gallons or 5 gallons of pure water or mineral water. Filling speed range: 150 bottles/hour. The equipment consists of a rinsing, filling and capping machine, an automatic bottle loading machine, a bottle washing machine, a bottle washing machine, a capping machine, a heating shrinking furnace, a conveying system, and a whole line control system.

Product Overview

- Filling volume: 19L/5 Gallon

- Production output:150 Barrels/hour

- Packing type: Barrel water

This depalletizer is used to unload the empty bottles from the full stack automatically, which can improve the site working condition and production efficiency to satisfy customer’s production and packaging requirements.

Product Overview

This depalletizer is used to unload the empty bottles from the full stack automatically, which can improve the site working condition and production efficiency to satisfy customer’s production and packaging requirements.

It is widely used in the sterilization of milk, fruit juice, tea drinks and other products. UHT sterilizer integrates heating, sterilization, cooling and heat recovery. The touch screen displays real-time production data online.

Product Overview

- Processing: Integrates heating, sterilization, cooling, and heat recovery

- Application: Fruit and vegetable juice, tea beverage, milk beverage and so on

In the production of dairy products, fruit juice, and beverages, there is always a small amount of residual liquid in the filling machine cylinder, tank, and related pipelines after the beverage flows through. Once the production is stopped for a long time, these residual liquids will cause fermentation, deterioration, and bacterial growth, and even corrode some metal surfaces over time. Therefore, CIP cleaning devices must be equipped in dairy products, fruit juice, and beverage production lines.

Product Overview

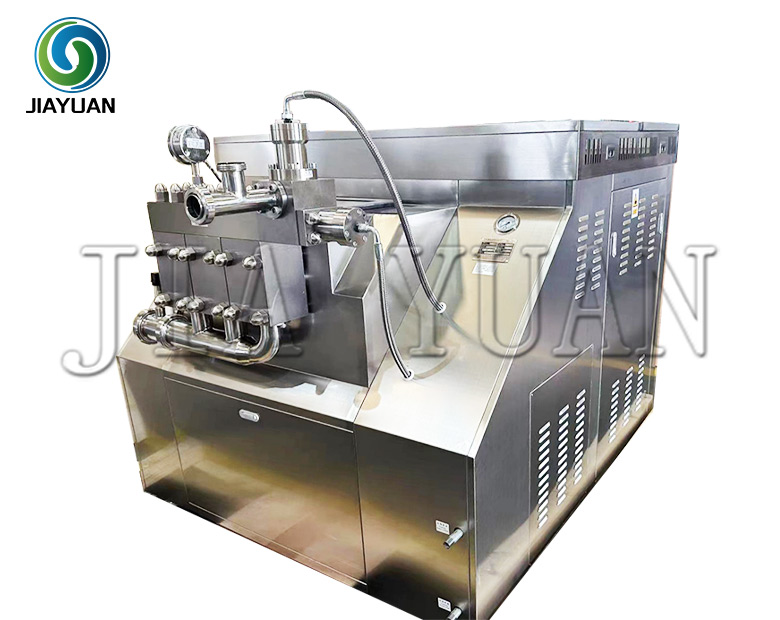

- Processing: Extruding, strong impacting, and decompression inflating

- Application: Milk, soy milk this kind of dairy foods

The pasteurizing tunnel is a specially designed pasteurization device for dairy, fruit juice, beverages, beer, food, and medicinal products, to be used after products have been filled or packaged into containers. This is the ideal device for materials to undergo sterilization, temperature control, and cooling for extending the product's shelf life.

Product Overview

- Equipment Type: High-temperature, high-pressure, water immersion sterilization

- Application: Dairy, fruit juice, beverages, beer, food, and medicinal products

In the production of dairy products, fruit juice, and beverages, there is always a small amount of residual liquid in the filling machine cylinder, tank, and related pipelines after the beverage flows through. Once the production is stopped for a long time, these residual liquids will cause fermentation, deterioration, and bacterial growth, and even corrode some metal surfaces over time. Therefore, CIP cleaning devices must be equipped in dairy products, fruit juice, and beverage production lines.

Product Overview

- Used for dairy products, fruit juice, and beverage production lines

The machine is mainly used in carbonating and mixing of carbonated beverage, such as cola, sprite, lemonade, coke, soft drink etc carbonated drinks. It is main equipment in beverage production line, especially the production of middle and superior quality drink.

Product Overview

- Capacity: From 1000 liters to max 25000 liters

- Application: Cola, sprite, lemonade, coke, soft drink etc carbonated drinks

Laser coding achieves excellent and lasting coding effect. It can be used to print QR codes, image logos, anti-counterfeiting codes, batch numbers, time and any text.

Product Overview

Laser coding achieves excellent and lasting coding effect. It can be used to print QR codes, image logos, anti-counterfeiting codes, batch numbers, time and any text.

The machine has the advantages of high automation, reliable control, convenient adjustment, and intelligent control. It is widely used in beverages, beer, chemicals, food, medicine and other industries. It can be used for secondary packaging of various canned and bottled beverages and can be used in conjunction with fully automatic filling production lines.

Product Overview

The machine has the advantages of high automation, reliable control, convenient adjustment, and intelligent control. It is widely used in beverages, beer, chemicals, food, medicine and other industries. It can be used for secondary packaging of various canned and bottled beverages and can be used in conjunction with fully automatic filling production lines.

The equipment is an automated system designed to efficiently package bottled water for commercial distribution. This allows the manufacturers to produce and supply water in bulk along with maintaining it’s standards.

Product Overview

- Bottle Type: Round/ Square/ Unique

- Production output: 10-30 bags/min

- Shrink film: PE, PP, PVC, POF, etc..

During the product forward conveying process, it can automatically group the product into package, so as to save time and enhance packing efficiency.Touch-screen operating panel with user-friendly interface and convenient parameter setup, absolutely an easy-to-operate machine.The ideal model of middle-speed heat-shrinking packager in the domestic market.

Product Overview

- Film material: PE, PP, PVC, OPF film

- Thickness: 0.03mm-0.15mm

- Width:200mm-600mm

- Capacity (production speed):0-20bags per minutes

Round bottle sticker labelling machine incorporates the latest sophisticated User Friendly Label Dispensing applicator System with a choice of Stepper or Servo Driven System. Machine with High Speed Label Sensor Facility and a unique Product Sensor which does not require any Teaching or settings.

Product Overview

- Label Roll Diameter:350mm

- Label Width*Length:10~110 mm*20~360 mm

- Speed:1-400 Products/Minute