Product details

100ml to 2L Semi Automatic PET Bottle Blowing Machine Making Machnie Price

Product overview

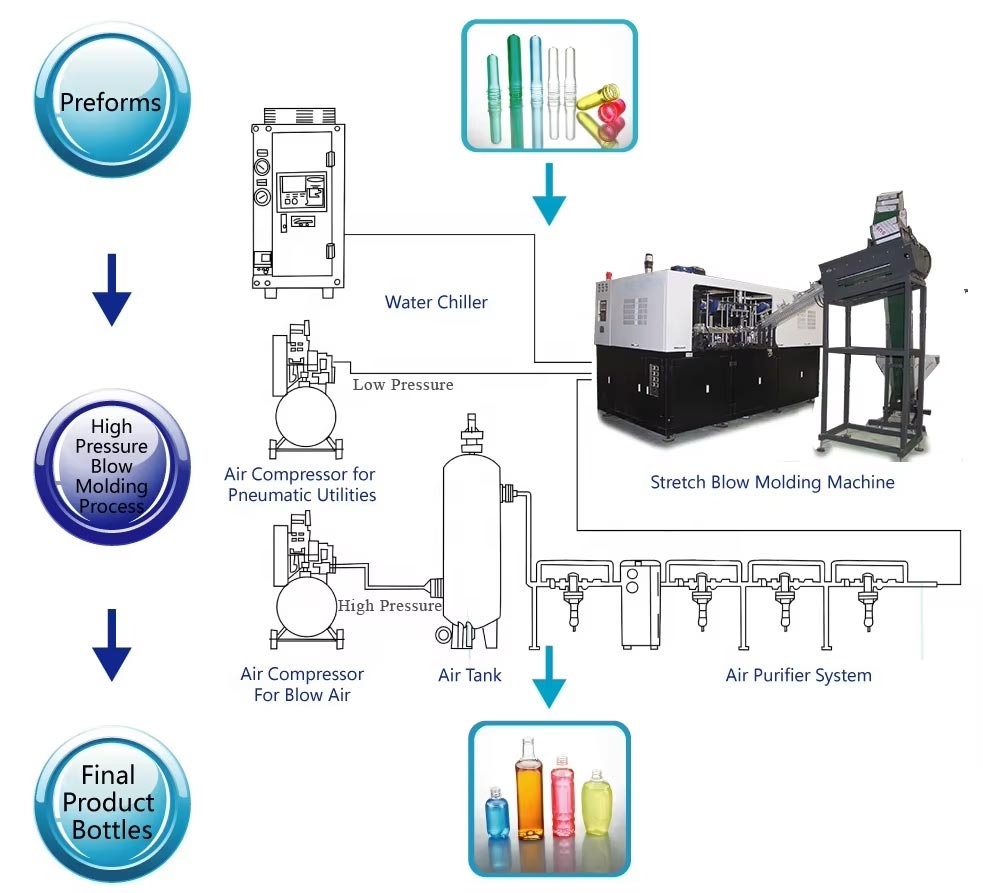

The blow molding machine is widely used to produce any shape of plastic from PET with neck finishes from 55 mm to 110 mm.Each set of MS Series machines is composed of two parts:

The Bottle Blower and the Infrared Preform Oven. The function of these two parts is:

Infrared Preform Oven: heat the PET preform to a suitable soft condition for blowing.

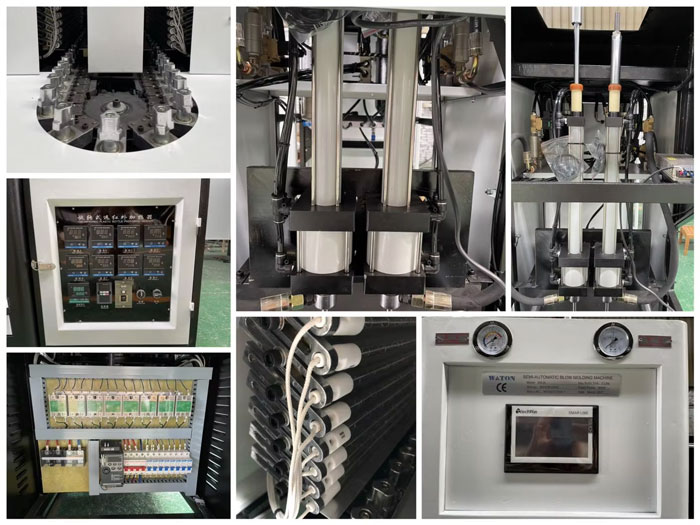

Blower: does the whole bottle blowing process, including sealing, stretching, blowing, exhausting, and blow mold’s moving, which is controlled by an advanced PLC control system.

Patent Blow Air Heating System & Pre-blow Function plays an important role in producing high-quality bottles, eliminating bottle whitening appearance.