Product details

2000-3000BPH Large Scale Bottle Automatic Liquid Drinking Water Filling Machine For Bottling Plant

Product overview

This series of equipment is used for the filling production of 3-10L large bottles of water, juice and oil. The machine integrates rinsing, filling and sealing. The output can be customized from 400 to 3000 bottles/hour;

Features:

This series of equipment is used for 3-10L large bottles of water and juice, oil filling production, the machine set rinsing, filling, sealing in one.

It is made of food-grade SUS304 stainless steel, and the output can be customized from 400-3000 bottles/hour;

Japan Mitsubishi PLC control, Taiwan Weilun touch screen human-machine interface, the whole line output can be adjusted and has good compatibility and expandability.

We can provide the whole production line equipment, with an output of 400-3000 bottles/hour.

We can customize various special equipment according to your needs, according to different bottle types, cap types, and filling materials.

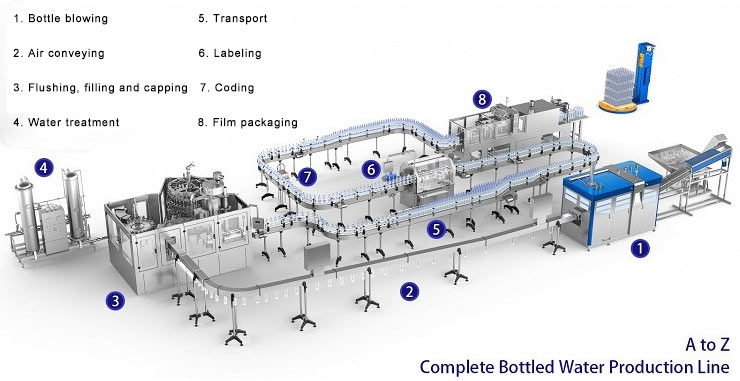

Workflow

Empty bottles will be sent to the filling host; filling host will empty bottles automatically flip-type rinsing and reset, flip-type rinsing to ensure that the inside and outside of the bottle to meet the relevant national health standards, filling using room temperature and atmospheric pressure valves, with a reflux device with a fast filling speed, filling stable, no leakage phenomenon, after the completion of the filling of the bottle using the capping or capping mechanism, the bottle for the capping operation.

Details

Rinsing part

The Washing mahcine is mainly to wash PVC, PET plastic bottles. The washing way is jetting, the structure is rotary. The machine can continuous automatic complete the processing: overturned bottle, turn bottle, wash bottle, water dripping. The whole processes include two steps, washing and dripping. It is a necessary machine for nature mineral water, pure water, and other liquid filling production line.

Filling

The filling machine is to fill water, juice etc non carbonated soft drink, it

also can use to fill vinegar, milk, etc;

Capping part

The capping machine can cap different kinds of bottles, it is reliable, easy to

operate and easy to maintain. It is the most popular rotary screw automatic folding capper.

Competitive Advantage

We can provide complete line plants, including water treatment, blowing machine, filling machine, labeling machine, packing machine, palletizer, and other equipment. With our rich experience in this business, we can provide a turnkey solution for you, from plant layout, bottle design, label design, production line setup, and operator training.

We provide a one-year guarantee and lifelong technical support. Any time the buyer has any problems, we will service or send professional engineers to help you debug.

Our service

- Complete line equipment

- Layout plant

- Bottle design

- Label design

- Preform/ cap/ label/ packing material provision

- 24/7 technical support