Product details

200ml to 2L High Speed Electric Full Servo PET Bottles Blowing Molding Making Production Machine

Product overview

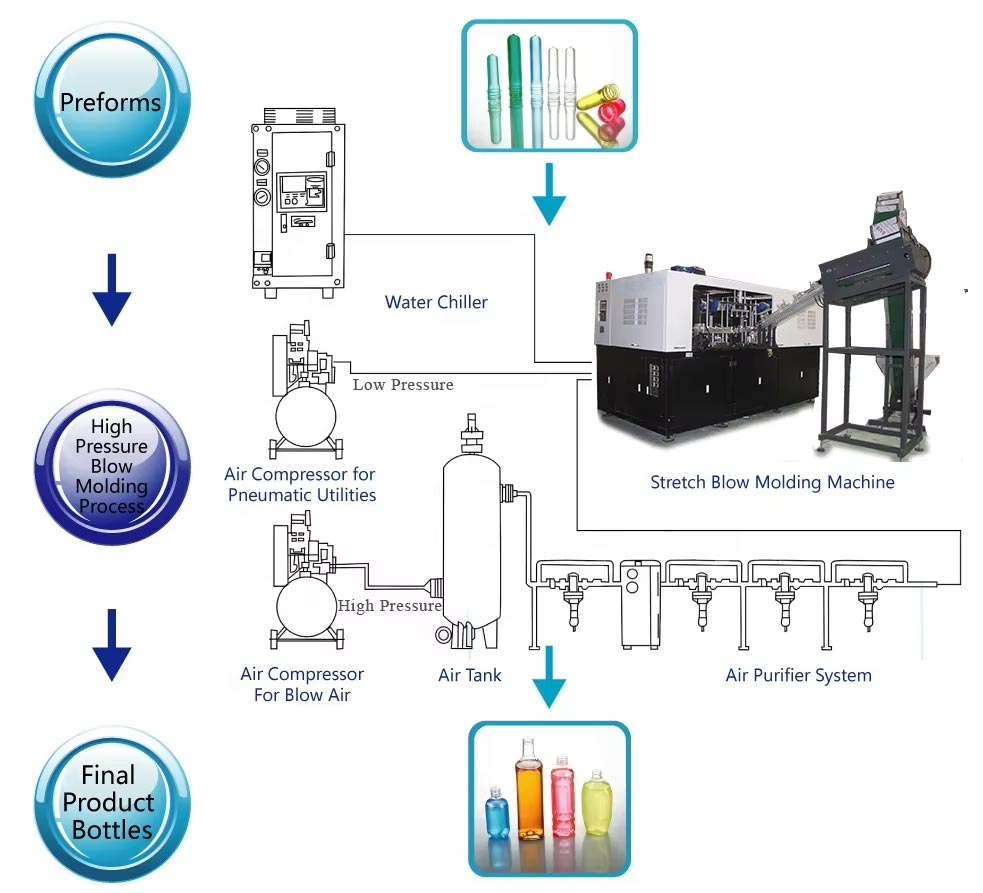

The blow molding machine is widely used to produce any shape of plastic from PET with neck finishes from 30 mm.

MAX6-2.5L linear full-auto stretch blow molding machine is full full-electric high-speed PET blow molding machine. It can produce all kinds of bottles below 2500ml, including food packaging bottles, edible oil bottles, soda and mineral water bottles, fruit juice bottles, wine bottles, cosmetics bottles, and so on.

ADVANTAGE

1. 6 Servo motors full coverage, fully electric. Cycle time is reduced from 4 seconds to 2 seconds, doubling production.

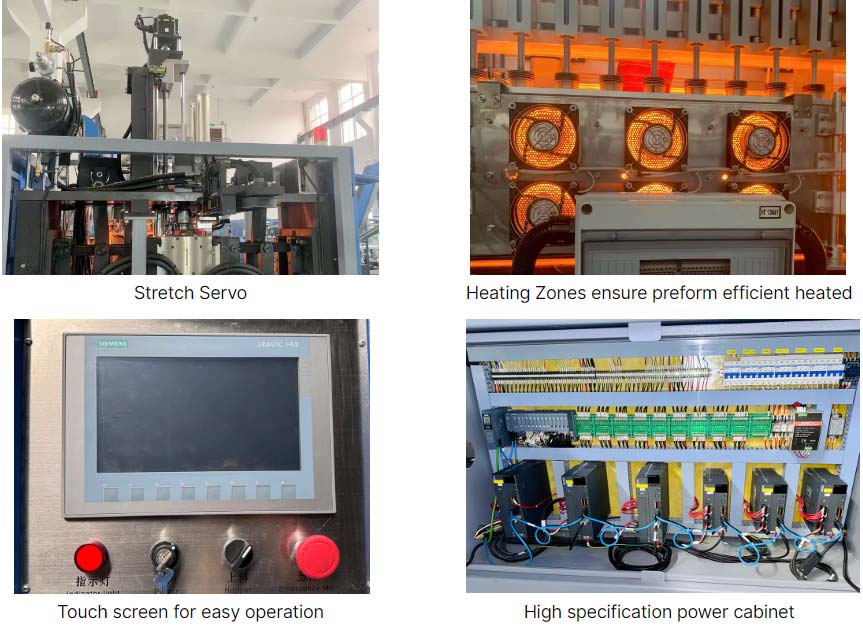

2. ServoMotion Control System

Using a PLC Servo System, the PTO system (Pulse/Train/Output servo positioning module) works on high-speed positioning.

3. Total of 4 heating ovens.

PET preforms sit next to each other, center distance 70mm, which makes the machine compact and saves much space.

4. Center Distance Varying System

During heating, preforms sit on the preform holder upside down (Bottleneck downward). This way preforms sit steadily, the preform neck can receive well cooling to avoid neck deformation.

5. After heating, PET preforms are gripped, turnover and separated by a servo system. The preform center distance is varied to 120mm by a servo motor. Preforms are fed into a mold with the neck upward.

6. Stretching & clamping systems are precisely controlled by a servo motor.

7. Mold fixed by drawer design, mold changeover can be easily done in half an hour.

8. Efficiency Constant Temperature Oven

9. Human Machine Interface

Overall computer control it’s easy to operate. Independent operation station makes it more flexible to arrange operating positions. Far from the eating area, ensure safety. Once the machine fails, the PLC automatically sends the fault diagnosis report to the touch screen, and the operator can quickly and accurately solve the trouble.

10. Safety

① A fully enclosed safety door system is used to ensure the safety of operators to the greatest extent possible.

② Multi-point photoelectric detection protects the positioning system, clamping system, and stretching system.

| Bottle blowing machine | |

| Model & Name | MAX6-2.5L |

| Brand | WATON |

| Overall Dimensions(mm)

Length*Width*Height(mm) |

Main machine:7500*2000*2400 |

| Weight | 9.6 (ton) |

| No.of Cavity | 6 cavities |

| Max. capacity | 2500 ml |

| Bottle Neck(max) | 30 (mm) |

| Bottle diameter(max) | 120 (mm) |

| Bottle height(max) | 350 (mm) |

| Install power | 145 (kw) |

| Production Consumption Power | 72 (kw) |

| Voltage | Customized |

| Theory production(based on 500ml water bottle) | 8,500-11,000BPH |