Product details

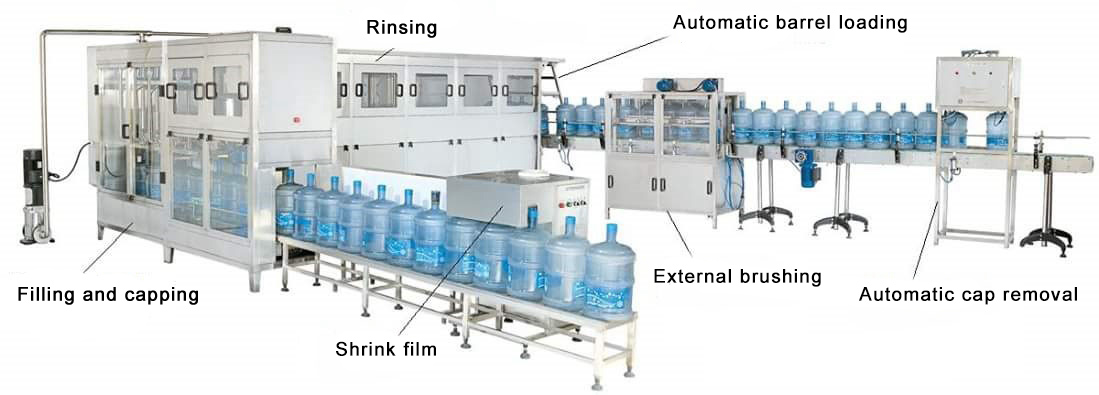

300BPH Barrels Pure Drinking Water Filling Plant Machine

Product overview

The gallon bottled water filling machine integrates rinsing, filling and capping, and is suitable for filling 3 gallons or 5 gallons of pure water or mineral water. Filling speed range: 300 bottles/hour. The equipment consists of a rinsing, filling and capping machine, an automatic bottle loading machine, a bottle washing machine, a bottle washing machine, a capping machine, a heating shrinking furnace, a conveying system, and a whole line control system.

Features:

This production line is mainly supplying 5 gallon barrels of drinking water, pure water, spring water filling production line, all adopt food-grade stainless steel 304 material, by automatic cap pulling machine, automatic outer brush machine, automatic inner brush machine, automatic barrel machine, washing and filling and sealing the main machine, automatic heat shrinkable oven, automatic bagging machine, controlled by PLC, the whole process to realize automation, making the equipment compact structure, operation and high efficiency.

The cleaning procedure of the 3-in-1 filling machine is divided into lye rinsing, then back to water cleaning, draining, sterilized water rinsing, draining, sterile water rinsing, and draining. The number of filling heads is 2 filling heads, the filling level can be adjusted by adjusting the filling time to regulate the level of the barrel water according to actual needs, the capping adopts crawler-type capping, and the capping pass rate is high.

Working principle:

This machine adopts program full automatic control, and its working process is as follows:

1. Bottle washing

The first station is the bottle placement station, the second station uses chlorine dioxide (CLO2 solution) for washing and disinfection, the third station is the pure water rinsing station, and the fourth station is the draining station.

2. Filling

The washed bottles are transported by the bottle washing transmission mechanism and fall on the bottle pusher. The bottle pusher cylinder moves to push the empty bottle to the filling position and start filling. The filling time is adjusted by the user according to needs.

3. Capping and pressing caps

When filling is completed, the next filling bottle will be sent to the capping mechanism to cap the filled bottle. The capped bottle will be pushed to the capping mechanism and the capping cylinder will press the bottle cap tightly. At this point, a washing and filling cycle is completed.

We can provide the entire production line equipment with an output of 120-2000 barrels per hour, and it can also be customized according to customer requirements.

Details

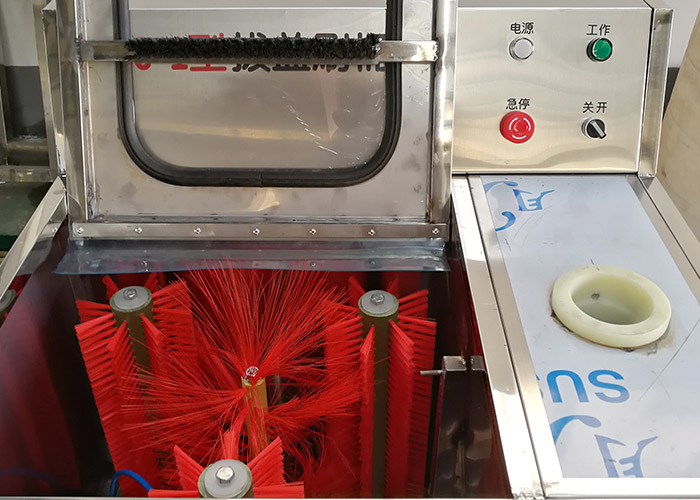

Full-automatic Cap Pulling and Brushing Machine

1. It is composed of a 25×25㎜ stainless steel square tube welded frame, transmission mechanism, pneumatic reversing cover pulling mechanism, electrical control, and water tank spray. It has the characteristics of smoothness, wear resistance, and corrosion resistance.

2. It integrates brushing, internal washing, and external washing. The three working states are completed in the same cycle, saving time, labor, and electricity.

3. Users can reasonably choose the circulating water supply, the non-circulating water supply, and the compound water supply mode according to their needs.

4. This machine is suitable for all-around effective brushing of the inner and outer walls of the barrel.

5. The operation is simple. Only one door opening and closing operation is required to complete the entire brushing process.

6. Pay attention to the power supply mode of this machine. N is the zero line. After the power is turned on, the water tank is filled with water to confirm the direction of motor rotation. Then turn on the panel power switch, and then open the flip cover to test run.

7. It is suitable for the separation of the lid and barrel of 3-gallon and 5-gallon drinking water recycling barrels. The barrel cover, after separation, is free of wear and deformation, and can be reused after disinfection, which improves the utilization rate of the barrel cover.

8. This machine uses air pressure as power, which is safe and reliable. The rated air source pressure is 0.5MPa/㎝2, the air intake volume is ≥0.1m3/minute, and the cap removal rate is 200-300 pieces/hour. Connect the air source, turn the recycling barrel upside down, insert the barrel mouth into the cap removal head, and then step on the foot switch. The barrel cover can be removed and slid out of the slide.

Automatic inner Brushing Machine

The automatic internal brush washing machine is used to clean the reusable 5-gallon bottles before filling to clean the dust and oil inside and outside the bottles. The main system adopts a high-grade nylon brushing system to clean the bottom, body and shoulder of the bottle, and is controlled by the PLC control system.

The operating procedures of the fully automatic internal and external bottle washing machine: bottle in; internal washing; bottle out. PLC automatic control, precise positioning, less labor and low work intensity.

The module adopts imported series binding, etc.

1. The main bracket is made of stainless steel, with a beautiful appearance and firm structure. The auxiliary bracket is connected to the main bracket to isolate the working area and support.

2. The electrical part consists of a PLC controller, an AC contactor, a fuse, and an air switch.

3. The pneumatic part consists of a cylinder, a pneumatic solenoid valve, and a pneumatic control electric control box.

4. The water tank is made of stainless steel with a reflux pipe and an adjustable hydraulic controller. Users can adjust the hydraulic pressure accordingly.

Automatic Outer Brush Machine

It adopts a new rotary all-around scrubbing process. The five-gallon bucket and the brush are in contact and move relative to each other to achieve the scrubbing effect. The frame, baffle, and control box are all made of 304 stainless steel. The operation control is divided into start/stop/emergency stop buttons.

This equipment adopts a rotary 6-station design, which can wash the outer barrel neck, outer barrel body, barrel bottom, and other parts, and achieve full scrubbing of the barrel outside. After scrubbing, rinse with clean water again to wash away the dirt. It is also equipped with a circulating water tank, a circulating water pump, a double-layer filter, a plexiglass cover, etc. It has significant advantages such as fast barrel scrubbing speed, better barrel scrubbing effect, and particularly strong stability.

Whenever there is a barrel blockage on the barrel outlet conveyor belt, the main power slips without stopping, and it resumes work automatically after the blockage is removed, which fully reflects the humanized design and is a trusted product of many large and medium-sized drinking water production companies.

Automatic Bagging Machine

1. The packaging speed can reach 800-1600 barrels/hour, which can save two to four operators, save about 100,000 yuan in labor costs each year, and also reduce the cost of bags. The cost of the film is about one-third lower than that of the old five-gallon bottle lifting machine.

2. After shrinking and sealing, the barrel bag fits the outer edge of the bucket, which is beautiful and compact;

3. The plastic film can protect the bucket and reduce wear.

Competitive Advantage:

we can provide complete line plants, inlcuding water treatment, blowing machine, filling machine, labeling machine, packing machine, palletizer and other equipment. We have rich experience in this busines, can provide turnkey solution for you from plant layout, bottle design, label design and production line set up to operators training.

We provide a one-year guarantee and lifelong technical support. Any time the buyer has any problems, we will service or send professional engineers to help you debug.

Our Service

1) Complete the line equipment

2) Layout plant

3) Bottle design

4) Label design

5) Perform/ cap/ label/ packing material provision

6) 24/7 technical support

| Parameter | |

| Operating voltage | AC220V, 380V (+10%,-10%)50HZ |

| Output capacity | 24V, 9V |

| Operating temperature | 5-45°C |

| Operating humidity | 40%-95% (non-condensing dew) |

| Anti-interference | In line with the IEC-801 GB98813 standard |

| Production capacity | 300 barrels / h |

| Filling capacity | 18.9L (5 gallons) |

| Specification of barrel and bottle | Φ270×490×Φ56 |

| Lid specification | Φ58×40 |

| Motor power | bottle pump 370W 380V 220V 50HZ |

| Filling pump | 750W 380V 220V 50HZ |