Product details

500ml PET Jar Bottle Servo Full Automatic Bottle Making Machine Blowing Machine Molding

Product overview

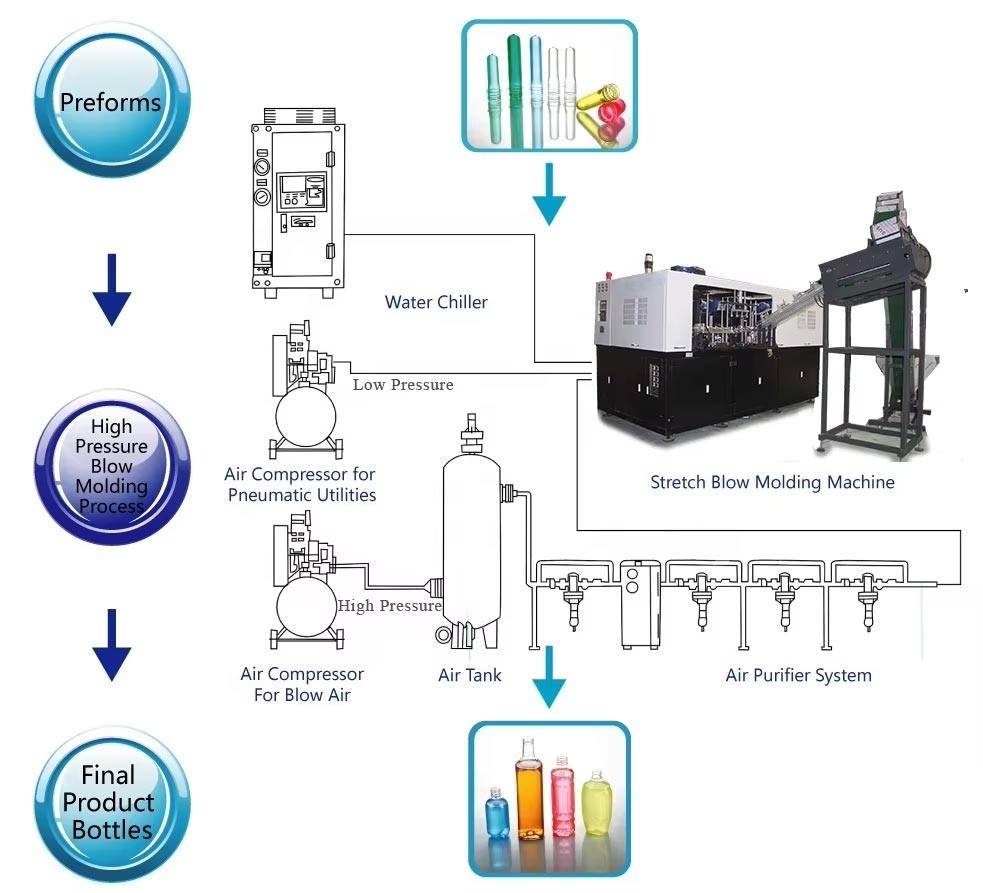

This fully automatic bottle blowing machine can be switched from 6-cavity/700ml to 3-cavity/200ml-2000ml, and can produce various types of bottles, including food packaging bottles, edible oil bottles, soda bottles, mineral water bottles, juice bottles, wine bottles, cosmetic bottles, etc.This is a flexible model linear full-auto stretch blow molding machine. It can switch from 6 cavities/700ml to 3 cavities/200ml-2000mll. It is a full-electric high-speed PET blow molding machine. It can produce all kinds of bottles, including food packaging bottles, edible oil bottles, soda and mineral water bottles, fruit juice bottles, wine bottles, cosmetics bottles, and so on.

| Model & Name | TURBO6-0.7L |

| Brand | WATON |

| Overall Dimensions(mm)

Length*Width*Height(mm) |

Main machine:4300*2150*2250

Auto-loader:1160*1600*3300 |

| Weight | 5.5(Tons) |

| No.of Cavity | 6 cavities |

| Cavity Center Distance | 76.2 mm |

| Max. capacity | 600 ml |

| Preform neck(inner dia.) | 18~38(mm) |

| Bottle diameter(max) | 69 (mm) |

| Bottle height(max) | 230 (mm) |

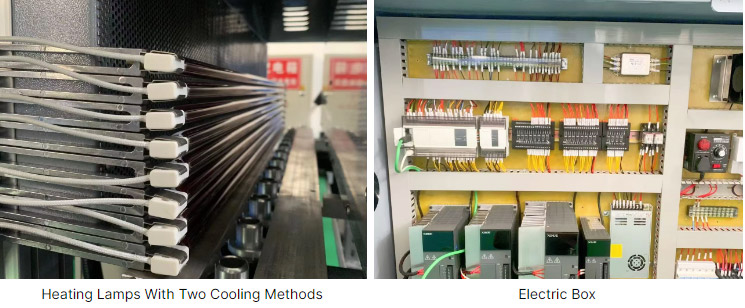

| Heating ovens | 4(unit) |

| Infrared lamps | 28 (pcs) |

| Max heating power | 65(kw) |

| Install power | 70(kw) |

| Voltage | customized |

| Theory production(based on 500ml bottle) | 9,000 - 10,000 BPH |

ADVANTAGE

Model TURBO6-0.7L Automatic Stretch-blow Machine is newly designed and reformed based on the previous experience of our manufacturer. Main feature of this model:

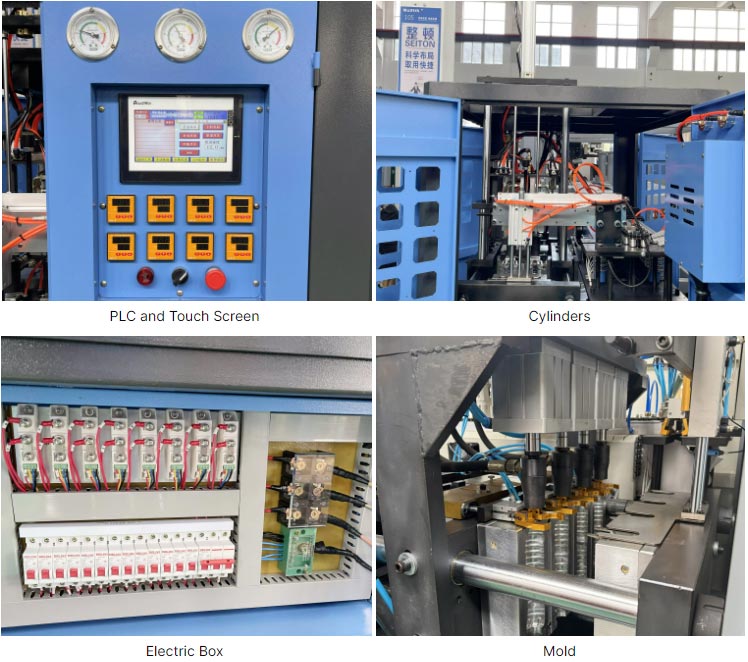

1. Full Servo control 4 main structures: Feeding, Shifting, Clamping, Stretching;

Preform Feeding System: servo motor partitioning effectively solves the problem of wear and deformation;

Preform Transfer System: performs horizontal movements driven by a Servo Motor. Make preforms 6pcs as one unit, overall simplified stepping motion, achieve high-speed positioning and smooth motion. To complete one step cycle, the Servo Motor drive gear rotates only one-third of a turn. The speed of the preform moving is 2 times that of the cylinder-driven way.

Mold Clamping System: The servo motor drives the rocker linkage, driving frame, and the bottom mold opening and closing. Reaction time is reduced by 50% compared to the traditional pneumatic model. Simple structure, no wear, longer use life;

Stretch System: Servo motor precisely controls the movement of stretch rods, and the accuracy can reach 1 mm. According to the adjustment of the bottle type, it greatly improves the blowing adjusting process of flexibility, accuracy, improves the quality of products.

2. Advanced PTO System (Pulse/Train/Output Servo Positioning Module) works on high-speed positioning, with higher speed, higher noise immunity, and precise positioning.

3. High speed, stable, low noise, 500ml production 4-cavity model 5,500BPH, 6-cavity model capacity 10,000BPH, 9-cavity model 13,000BPH.