Product details

Automatic Bottle Making Machine 2 Cavities 5L 10L Blow Molding PET

Product overview

The blow molding machine is especially used to produce 3-gallon and 5-gallon bottles and is widely used to produce any shape of plastic from PET with neck finishes from 55 mm to 100 mm.

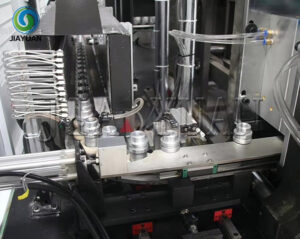

BS5L 2-cavity linear full-auto stretch blow molding machine is an economical full-automatic PET bottle blowing machine independently developed by WATON Machinery. It is economical, fast and convenient. It can produce all kinds of bottles below 5L, including food packaging bottles, edible oil bottles, soda and mineral water bottles, fruit juice bottles, wine bottles, cosmetics bottles, and so on.

1. Upgrade to Servo Motor Drive:The Perform Transfer System performs horizontal movements driven by a Servo Motor. Make preforms 4pcs as one unit, overall simplified stepping motion, achieve high-speed positioning and smooth motion. To complete one step cycle, the Servo Motor drive gear rotates only one-third of a turn. The speed of the preform moving is 2 times that of the cylinder-driven way.Mold Clamping System: The servo motor drives the rocker linkage, driving frame, and the bottom mold opening and closing. Reaction time is reduced by 50% compared to the traditional pneumatic model. Simple structure, no wear, longer use life.2. Mold fixed by drawer design, mold changeover can be easily done in half an hour.3. Efficiency Constant Temperature Oven:a. Use the most advanced high-frequency Infrared Lamp, increasing heating efficiency by 30%-50%.b. Each layer of the lamp is separately controlled, with an assistant ruler on the machine.c. Intelligent temperature control system. The temperature detector feeds back to the PLC automatically, the PLC makes an accurate judgment, and then controls the circulation of air in the oven. It leads to constant temperature in the Oven, free from voltage fluctuations and ambient temperature. It works when a large ambient temperature difference (-28~45℃) existsd. Perform self-rotation System, ensure every side of every performance is heated evenly, which ensures the quality of the blown bottle. (thickness up to 4.5mm)e. Neck Cooling in the Oven. Preform Necks are cooled by recycling water, which avoids neck deformation

1. Upgrade to Servo Motor Drive:The Perform Transfer System performs horizontal movements driven by a Servo Motor. Make preforms 4pcs as one unit, overall simplified stepping motion, achieve high-speed positioning and smooth motion. To complete one step cycle, the Servo Motor drive gear rotates only one-third of a turn. The speed of the preform moving is 2 times that of the cylinder-driven way.Mold Clamping System: The servo motor drives the rocker linkage, driving frame, and the bottom mold opening and closing. Reaction time is reduced by 50% compared to the traditional pneumatic model. Simple structure, no wear, longer use life.2. Mold fixed by drawer design, mold changeover can be easily done in half an hour.3. Efficiency Constant Temperature Oven:a. Use the most advanced high-frequency Infrared Lamp, increasing heating efficiency by 30%-50%.b. Each layer of the lamp is separately controlled, with an assistant ruler on the machine.c. Intelligent temperature control system. The temperature detector feeds back to the PLC automatically, the PLC makes an accurate judgment, and then controls the circulation of air in the oven. It leads to constant temperature in the Oven, free from voltage fluctuations and ambient temperature. It works when a large ambient temperature difference (-28~45℃) existsd. Perform self-rotation System, ensure every side of every performance is heated evenly, which ensures the quality of the blown bottle. (thickness up to 4.5mm)e. Neck Cooling in the Oven. Preform Necks are cooled by recycling water, which avoids neck deformation

| Models | BS-5L2 | |||

| Max bottle size | 5L | |||

| Theoretical Capacity | 1200-1600BPH | |||

| Mold Cavities | 2 | |||

| Neck Size | 38-100mm | |||

| Max. Volume | 5000ml | |||

| Advantages | High productivity, easy to operate, and long-term after-sales service. | |||

| Models | BS-5L2 | BS-10L2 | BS-20L2 | |

| Theoretical Capacity(BPH) | 1,200~1,600 | 900~1,000 | 400~500 | |

| Mold Cavities | 2 | 2 | 2 | |

| Bottle | Neck Size | 55-100mm | 55-100mm | 55-100mm |

| Max. Volume | 5000ml | 10000ml | 20000ml | |

| Max. Diameter | 180mm | 260mm | 280mm | |

| Max. Height | 350mm | 420mm | 500mm | |

| Blowing Method | stretch blow molding | stretch blow molding | stretch blow molding | |

| Main Machine Size | 3000*1800*2400mm | 3300*2000*2200mm | 4200*2100*2400mm | |

| Main Machine Weight | 2500KGS | 3600KGS | 5000KGS | |