Product details

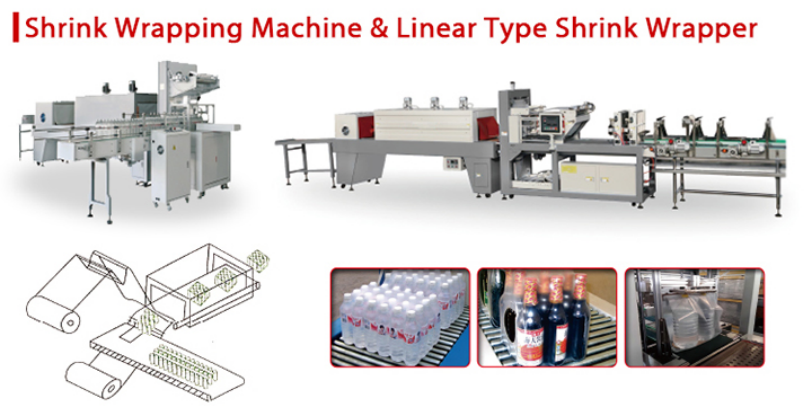

Automatic Bottle Sleeve Plastic PE/PVC Film Heat Sealing Shrink Wrapping Machine

Product overview

During the product forward conveying process, it can automatically group the product into package, so as to save time and enhance packing efficiency.Touch-screen operating panel with user-friendly interface and convenient parameter setup, absolutely an easy-to-operate machine.The ideal model of middle-speed heat-shrinking packager in the domestic market.

A full automatic shrink packaging machine can not only be used, but used simultaneously with other equipment to form a packaging production line. It can automatically array, aggregate, and align PET beverage bottles or other similar articles, then package them with shrinking film, and finally produce finished products after shrinking by heating, cooling, and forming. The packaged product is firmly bound with an excellent appearance, which can be opened conveniently. Therefore, it is widely used in industries such as foodstuffs, medicine, chemicals, and other light industrial products.

1) The temperature can be controlled automatically and changed as required.

2) Isothermal sealing cutter

3) Original guide bar cylinder with steady operation

4) Programmable logic controller (PLC) control

5) Non-bottom support packaging, suitable for packaging with different bottle diameters and different combinations

6) Simple operation and easy repair.

Finally products

| Item | Technical data | |||

| 1 | Import Power | 25KW | ||

| 2 | Import Voltage | ∮3, 380/220 VAC | ||

| 3 | Working air pressure | 0.6Mpa | ||

| 4 | Matching air compressor requirements | Discharge pressure:0.8Mpa; Flow rate:0.25m3/min |

||

| 5 | Capacity (production speed) | 0-20bags per minutes | ||

| 6 | Outline dimension of the equipment (mm) | L5970*W3510*H1940mm | ||

| 7 | The largest dimension of the wrap-page (mm) | L600*W400*H350mm | ||

| 8 | The highest temperature of the heat shrink furnace | 160-260℃ Can adjust freewill | ||

| 9 | Conveyor Height | 950mm±50mm | ||

| 10 | Length of feed conveyor | 2750mm | ||

| 11 | Actual power consumption | 15Kw/hour | ||

| 12 | Equipment weight | 1.6T | ||

| 13 | Film material | PE, PP, PVC, OPF film, Thickness: 0.03mm-0.15mm, Width:200mm-600mm | ||

| Technical Parameter | ||||

| Model | WD-10(Linear type) | WD-15(Linear type) | WD-20(Linear type) | WD-25(Linear type) |

| Machine dimension(mm) | 6500*3200*2100 | 8500*3200*2100 | 13200*1100*2100 | 13840*1100*2100 |

| Shrink tunnel dimension(mm) | 1800*650*450 | 1800*650*450 | 1800*650*450 | 2500*700*450 |

| Max.package dimension(mm) | 600*400*350 | 600*400*350 | 600*400*350 | 600*400*350 |

| Packing speed (bundles/min) | 8-10 (pcs/min) | 14-15 (pcs/min) | 16-20 (pcs/min) | 20-30 (pcs/min) |

| Work voltage/power | 380V 19kw | 380V 19kw | 380V 30kw | 380V 30kw |

| Working pressure | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa | 0.6-0.8Mpa |

| Total weight | 1600kg | 2000kg | 2500kg | 2800kg |