Product details

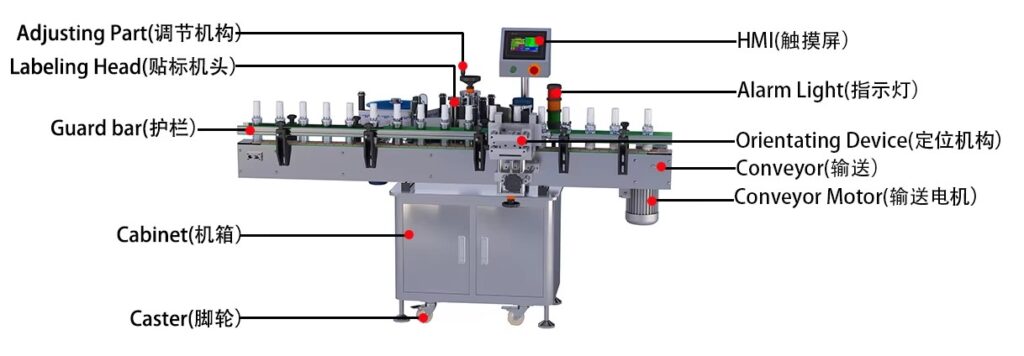

Automatic Self-adhesive Sticker Labeling Machine Shrink Sleeve Labeling Machine

Product overview

Round bottle sticker labelling machine incorporates the latest sophisticated User Friendly Label Dispensing applicator System with a choice of Stepper or Servo Driven System. Machine with High Speed Label Sensor Facility and a unique Product Sensor which does not require any Teaching or settings.

Round bottle sticker labelling machine incorporates the latest sophisticated User Friendly Label Dispensing applicator System with a choice of Stepper or Servo Driven System. Machine with High Speed Label Sensor Facility and a unique Product Sensor which does not require any Teaching or settings. The Machine is suitable for Labelling on Round Vials, bottles, jars, and other round objects. It is available with a speed range of 1-400 Products per minute, depending on product diameter and label size.

There are two labels (front and back, two labels on one side), and a labeling machine according to customer request.

Working principles of the sticker labeling machine

At the beginning of the working process, the bottles are fed to the labeling machine at a constant speed on the conveyor belt. The mechanical fixing device separates the bottles by a fixed distance and pushes the bottles along the conveyor belt. The mechanical system of the labeling machine includes a driving wheel, a labeling wheel, and a reel.

The driving wheel drags the label tape intermittently, the label tape is pulled out from the reel, and the labeling wheel presses the label tape on the bottle after passing through the labeling wheel. An open-loop displacement control is used on the reel to maintain the tension of the label tape. Because the labels are closely connected on the label tape, the label tape must constantly start and stop.

The label is attached to the bottle when the labeling wheel moves at the same speed as the bottle. When the conveyor belt reaches a certain position, the label belt drive wheel will accelerate to a speed matching the conveyor belt, and after the label is applied, it will decelerate to a stop.

| Technical Parameters | |

| Dimension | L 2100mm * W 900mm * H 1500mm |

| Voltage | 220V/50Hz |

| Power | 2000 W |

| Production Capacity | 0-40m/min |

| Label Roll Core | 76 mm |

| Label Roll Diameter | 350 mm |

| Label Width | 10~110 mm (special size can be customized) |

| Label Length | 20~360 mm (special size can be customized) |

| Bottle Diameter | 30~90 mm (special size can be customized) |

| Bottle Height | 30~200 mm (special size can be customized) |