Product details

Glass Bottle 3 in 1 Machine Energy Drink Soda Filling Capping Machine Cost

Product overview

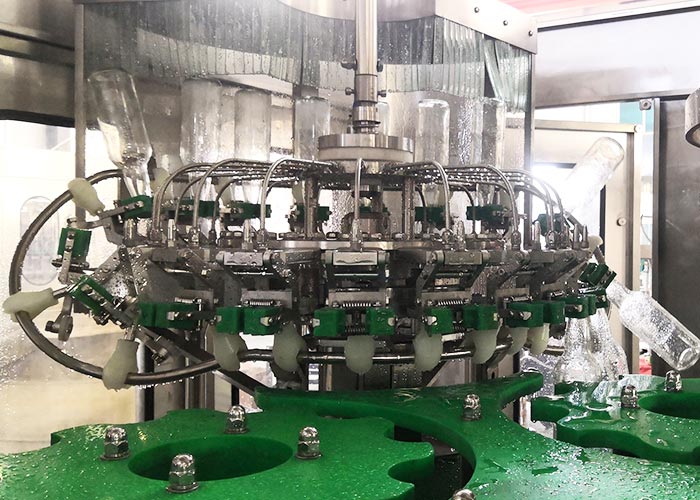

I would like to introduce you our carbonated soft drink filling machine, which is an all-in-one machine, with a rinser, filler and capper integrated in one unit, for the production of carbonated drinks in glass bottles, such as cola, mineral water, soda, energy drinks, soft drinks, and can also fill water or juice. The machine has multiple models, with a capacity from a minimum of 400BPH to a maximum of 25000BPH, and bottle sizes from a minimum of 200ml to 2000ml.

Features:

We supply complete solution for the beverage/pure water filling plant ,including Water treatment system / Carbonated beverage mixing system / Washing filling capping machine / Code printer / Pasteurizer tunnel / Automatic labeling machine / Automatic packing machine / Automatic Palletizer system.

1. 100% Customizable: Our Automatic Glass Bottle Beer Filling Machine can be tailored to meet your specific needs, with bottle sizes, capacity, and materials customized to your preference. * 100% customized solution for your bottling needs

2. Robust Performance: Equipped with advanced PLC+ Touch Screen control, this machine boasts a powerful filling capacity of 400-2500 bottles per hour, ensuring a lifetime of up to 8-10 years of reliable service. * Advanced PLC+ Touch Screen control and 8-10 years of dependable service

3. Environment-Friendly: Our filling machine uses glass or plastic bottles and operates with a low-noise, energy-efficient design, contributing to a reduced carbon footprint. * Environmentally friendly design, lower noise, and energy efficiency

4. User-friendly: The machine is designed for ease of operation, allowing for quick and efficient filling, capping, labeling, and packing of products - perfect for beginners or experienced operators alike. * Easy to operate and suitable for both beginners and experienced users.

Details

Rinsing System

The innovative water distribution system of the liquid filling machines for sale optimizes water conservation. The patented bottle clamp design features 304 stainless steel claws with food-grade plastic pads to prevent scratches and protect the bottle's mouth, enhancing the drinking experience and avoiding any injury to consumers. The food-grade 304 stainless steel flushing head and water injection design provide additional cleanliness while conserving even more water.

Filling Part

Our fill bottling machine is satisfying the market of JNSDIT (juice, nectar, soft drink, isotonics, tea) filled in glass bottles. The liquid filter has 14-40 filling heads, which is more efficient than a machine that has a single head.

Capping part

A capping solution that is unparalleled and uses a solitary container for optimal bottle excellence and drink protection. It enhances the speed of juice filling and seals bottles promptly, preserving top-notch product standards and preventing any secondary contamination.

| Containers and specifications | ||||

| Complete full automatic 3-in-1 glass bottle beer filling machine 400- 25000 BPH | Carbonated water / Soft Drink / Beer | |||

| Material | Shape | Filling volume | Filling level(mm) | Neck type |

| Glass Bottle | Round Bottle | 200-2000ml | Distance from bottle neck

According request |

Screw cap Crown cap Ring cap |

| Adjustable specifications of the bottle type | (Middle Mould Base) Bottle diameter: Φ50~Φ85mm Bottle Height: 105~300mm |

|||

| Customers need to buy additional change-over parts for the different bottles. If using square bottles, then a bottle separating system will be added. |

||||

| Carbonated Drink Preparation | Syrup melter / Mixing machine / Filter / CO2 Filter / CO2 Mixer ...../ | |||

| Filling Precision | Washing bottle - CO2 into bottle - Vacuum - CO2 - Vacuum - Filling Beer - Capping | |||

| Container Label & Control Mode | Packaging system | Palletizing system | ||

|

Hot Melt Roll-Fed PVC Shrink Label Full Label/ Half Label Manual / Automatic |

Packing system | Min, Spec. | Manual

Low-position gantry palletizer Robot Palletizer High-position gantry palletizer Single Arm Palletizer Manual Palletizer |

|

| Manual

Film shrinker Wrap Around Packer Robert Packing Machine |

1*2

2*3 3*4 4*6 3*5 |

|||

| User Ambient Conditions | Temperature:10~40℃; Humidity: No dew | |||

| User Electrical Supply Specification | Voltage:380V±5%, 3phase; Frequency:50HZ±1% | |||