Product details

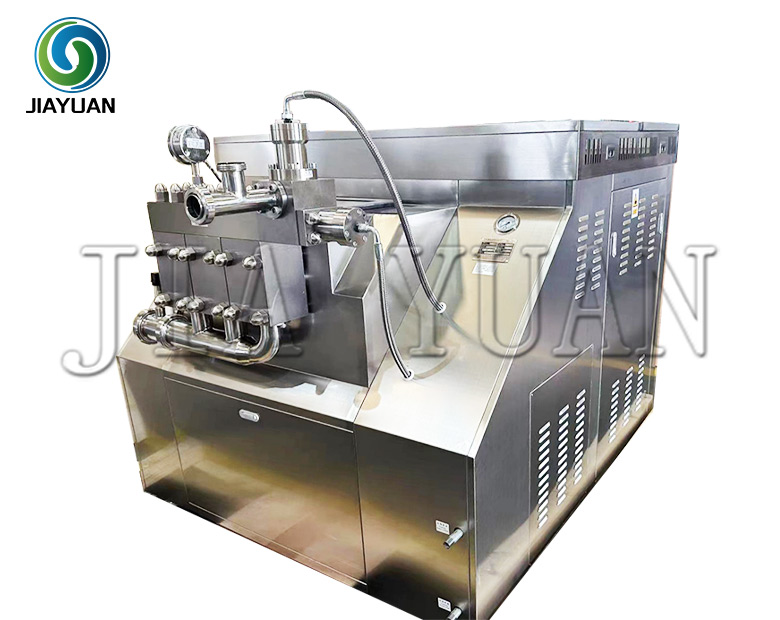

High Pressure Homogenizer Dairy Homogenization Machine

Product overview

In the production of dairy products, fruit juice, and beverages, there is always a small amount of residual liquid in the filling machine cylinder, tank, and related pipelines after the beverage flows through. Once the production is stopped for a long time, these residual liquids will cause fermentation, deterioration, and bacterial growth, and even corrode some metal surfaces over time. Therefore, CIP cleaning devices must be equipped in dairy products, fruit juice, and beverage production lines.

Main technical parameters of the emulsifying homogenizer

It can be used as high high-pressure homogenizer.It can cause the material to thin and mix under the three actions of extruding, strong impacting, and decompression inflating. It is an important piece of equipment for food, dairy, drink processing, and so on. It can cause the fat globules to thin while homogenization under high pressure in milk, soy milk this kind of dairy foods. And cause its products to be easy to digest and absorb, and to improve the dietary value. It can improve the fineness and the fraction void of the fluid material, as well as its intrinsic quality, while being used in the processing of ice cream in this kind of production. If used in the production of emulsion, glue, fruit juice, syrup, and so on, it will prevent or reduce the delamination of the material, improve the appearance of the material, and make the luster more bright, the fragrance thicker, and the taste mellower.

Be used as high high-pressure delivery pumpIt is an important equipment during the production of powdered articles, as the fluid material produces high pressure when through the equipment, and is made into powder after passing through the spray drying device. This equipment can also be used in the homogenizing, high-pressure transportation, and high-pressure spray situations of other fluid materials. It is composed of a frame, a wheel box, a pump body, a pressure meter, a homogenizer, and so on.

| Standard rated capacity: | 500 -35000L/H |

| Standard rated working pressure: | 1800 bar |

| Product process viscosity: | < 2000 cps |

| Large feed particle size: | <500um |

| Working pressure display: | pressure sensor/digital pressure gauge |